Registration is now open for ShipTech 2024, which will be held on 21-22 Mar 2024 at the Charleston Marriott in Charleston, SC.

Visit the websites to register for ShipTech and lodging information.

The TEAM

CNM is a government / industry / academia partnership. Organizations and individuals from a variety of disciplines are engaged as needed to solve technical challenges and improve manufacturing processes.

The MISSION

CNM will identify, develop, and deploy metalworking and related manufacturing technologies to reduce the cost and time to build and repair key naval platforms and other relevant industries.

The MODEL

CNM is a Navy ManTech Center of Excellence, with single-point contracting through ATI. Teamed with the Edison Welding Institute (EWI), CNM provides robust capabilities to address the DoD manufacturing industrial base, including state-of the-art metalworking labs and deep expertise in key technology areas. From virtual project management to innovative prototypes, CNM delivers tailored solutions

INNOVATIONS IN METALWORKING

from Materials to Design to Manufacturing

A Navy-focused/Industry-driven Enterprise

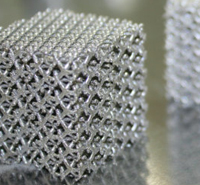

Metals and Advanced Metallic Materials

Additive Manufacturing

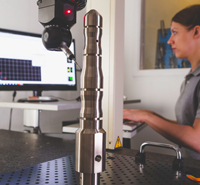

Joining Techniques

Surface and Heat Treatments

Material Characteristics and Testing

Process Design Control

Industrial Base Infrastructure